bibliográficos y se tomaron muestras, que luego fueron sometidas a pruebas de laboratorio mediante los métodos de análisis granulométrico, fluorescencia de rayos X y difracción de rayos X en la UEM. Se realizaron caracterizaciones químicas comparativas de las masas sólidas de las probetas estándar y de las incorporadas con porcentajes de RBRO y RFC, y sometidas al ensayo de resistencia a la compresión (RC) en el LEM, con el fin de evaluar mejor su desempeño. Se demuestra que el RBRO es de naturaleza básica y tiene los siguientes elementos: Si y Fe, con Calcita, Cuarzo, Anortita, Ilita y Magnesio en la gama mineral. El RFC se encuadra en el rango de los agregados finos y tiene como elementos químicos mayoritarios: Fe, Si, S, Al, Ca, Ti y K, dentro de la gama mineral caolinita, cuarzo, paligoresquisto, moscovita, siderita y dolomita. Las pruebas RC en las muestras AM1 (6 %), AM3 (23 %) y AM4 (29 %) arrojaron resultados satisfactorios, permitiéndoles cumplir con los estándares de resistencia admisibles en la norma actual de Mozambique. RBRO y RFC tienen potencial para ser utilizados en la producción de bloques ecológicos. Palabras clave: material de construcción, edificio ecológico, lodos residuales

Introduction

The impacts of urban population growth and the country's development in general can become a problem in the long term. Schneider, Friedl & Potere (2009) show that the impacts resulting from the expansion of agglomerations and the urban population, such as the destruction and contamination of ecosystems, are not the only problems.

Mozambique is characterized by a wide geological diversity, with various types of lithology ranging from the Archaic to the Quaternary (GTK Consortium, 2006), in which over time various geological processes have resulted in the formation and deposition of different mineral resources and various ornamental rocks, which have favored the discovery of deposits, thus contributing to the country's economic growth and development in the extractive area.

In Manica province, specifically at the HuaxiHelinMining landfill, abrasive sludge is deposited as a result of granite processing. According to Silva (1998), abrasive sludge is a mixture made up of metallic iron grit, lime, ground rock and water, which results from the industrialization of rocks, generating huge quantities of solid waste that can be harmful to human health.

Tete Province, specifically in the Moatize District, has one of the largest coal deposits in the country with reserves estimated at more than 2.5 billion tons, which should be exploited for a period of 35 to 40 years (José & Sampaio, 2012). Although mineral coal is an important energy and metallurgical resource in today's society, its exploration, processing and use are potentially polluting activities, most often releasing some heavy metals, which degrade the physical environment (Macie, 2015).

The aspects described above demonstrate the need to minimize the possible impacts of the deposition of abrasive sludge and fine coal tailings and, above all, the means of reusing this waste. There are currently several applications worldwide for the reuse of waste generated by the mining industry, which is used as a raw material and in some cases has been an alternative used in the production of ceramic materials. According to Menezes et al. (2002), the reasons for reusing waste are generally the conservation of non-renewable sources, the depletion of natural reserves and improving the health and safety of the population.

The probable impacts that can be caused by the deposition of fine coal tailings are the generation of acid mine drainage (AMD), changes in the land and slopes stability, changes in the topographic surface, breaches of tailings containment dams, massive disposal (in inappropriate places and disposed of indefinitely), landscape alteration and loss or destruction of soils and subsoils (Prochnow & Porto, 2000). Abrasive sludge and fine coal waste occupy an extensive area and have not been reused in Mozambique, so one of the ways of reusing this waste is basically to incorporate it as partial alternative aggregates in the production of ecological blocks. This perspective is part of the construction sector's aim to social development contribution, meeting people's basic needs, reducing the housing deficit, for example.

The objective of this study is to evaluate the potential of using the abrasive slurry resulting from granite processing at the HauxiHelinMining Company in Manica province and fine coal tailings from the Benga-ICVL Mine in Tete province as partial alternative aggregates in the ecological building blocks´production.

Materials and method

In order to fulfill the objectives, the samples acquired were the result of fieldwork carried out in two study areas:

-Fieldwork was carried out in Manica Province, where the abrasive slurry samples were collected from the landfill of the company responsible for processing and beneficiating granite at Huaxi Helin Mining;

-Fieldwork was carried out in Tete province, where samples of fine coal tailings were collected from the fine tailings dam at the Benga-ICVL Mine.

Abrasive sludge sampling

For the collection of RBRO, it was carried out fieldwork in Chimoio, Manica province, over two months. At this stage, there were taken abrasive slurry residue´s samples.

Fine coal tailings´sampling

At this stage, there were selected the needed CFR quantities to fulfill the objectives. To collect the CFR, it was carried out fieldwork over 14 days at the active tailings dam called "Tailling Dam" in the CHPP (Coal Handling and Preparation Plant) of the Benga Mine section, Moatize District, Tete province, it is located around 1 km south of the Processing Plant.

Laboratory experiments

This stage consisted of characterizing the abrasive slurry from the Huaxi Helin Mining Company landfill and the fine coal tailings from the Benga Mine through physical and mechanical experimental activities. The tests were carried out at the Mozambique Engineering Laboratory (LEM), located in Maputo City. Subsequently, there were carried out chemical and mineralogical analyses on the abrasive slurry and fine coal tailings samples, as well as on the specimens´solid masses at the Chemistry Department, Eduardo Mondlane University.

To fulfill all the objectives, there were prepared and characterized the samples according to the established methods and there were produced ecological building blocks´ samples using the design provided by the LEM in the Construction Materials and Structures in the Ceramics Sector Department for reducing the amount of fine sand from the waste.

After production, there were subjected the specimens to resistance mechanical tests to compression and there were also carried out the chemical characterizations of the specimens’ solid masses, culminating in the correlation of all the data in a simple and objective way in order to synthesize and organize them using graphs and tables.

To carry out the laboratory tests in this study, there were collected and determined all the necessary materials, electronic and mechanical equipment, which had its specific function in the evaluations (Table 1).

Table 1. Materials used in laboratory tests

|

Materials |

Trademark |

Source |

|

Potable Water |

- |

FIPAG |

|

Fine Sand |

- |

Areeiro de Moamba |

|

Rough Sand |

|

Incomati River |

|

Cement |

Limestone Portland 42,5 N |

Mozambique Cement |

|

Abrasive mud |

- |

Huaxi Helin Mining |

|

Fine coal refuse |

- |

Benga Mine-ICVL |

Sample preparation

To prepare the samples used in this work, there were dried the RBRO and RFC in the open air for 24 hours in order to remove moisture, then, there were placed on trays and dried in the ventilated oven with the fine and coarse sand at 105 oC for 24 hours.

However, the abrasive slurry had to be sieved through a 10 mesh number in order to exclude any particles with larger diameters that were not part of its original composition

RBRO chemical and mineralogical characterization

To know the chemical and mineralogical characteristics determined the RBRO potential use as a mineral additive, before the experimental phase began to determine this waste incorporation percentage in the building production.

RBRO chemical characterization

It was determined the chemical characterization in the School of Science chemistry laboratory at UEM. Through the Hydrogenionic Potential (pH), which is a preliminary physical analysis, it consisted of determining the total concentration of potentially toxic metals present and verifying whether or not the waste would result in the acid mine drainage generation. The RBRO underwent alkalinity monitoring using a EutechInstruments pH-700 meter and the combined glass electrode.

Subsequently, it was analyzed the sample in powder form using the chemical analysis technique of energy dispersive X-ray fluorescence (EDX) on a Shimadzu EDX-7000 device, with a sample holder aid. This characterization consisted of qualitatively demonstrating the concentration percentage values of the RBRO chemical elements.

RBRO mineralogical characterization

It was determined the mineralogical characterization by X-ray diffraction (XRD) analysis, using an equipment piece called an Olympus BTX-525 X-ray diffractometer. It was analyzed the RBRO sample as a powder that passed through a 150 μm mesh sieve and it was deposited on a glass slide with a circular cavity.

RFC physical characterization

It was possible to carry out the RFC physical characterization through the particle size analysis (GA), which consisted of sorting it through sieves with different sieves in descending order to categorize the retained mass particles on the various sieves. It was carried out this test based on the NP 933-1 (2014) specifications used at the Mozambique Engineering Laboratory.

RFC chemical characterization

It was qualitatively checked the chemical elements´ concentration percentage values present in the RFC by using the X-ray fluorescence (XRF) chemical analysis technique.

RFC mineralogical characterization

It was determined the RFC mineralogical characterization by using X-ray diffraction (XRD) analysis on equipment called a PAN AlyticalEmpyrean diffractometer and there were identified the mineralogical phases by using the X'PertHigh Score Plus software and the relative amounts of phase (% by weight), the RFC sample was analyzed in powder form.

RBRO and RFC incorporation in the ecological building production

In order to determine how the RBRO and RFC would be incorporated, it was carried out an experimental plan, which consisted of determining the total number of specimens to be produced for the mechanical resistance test.

To do this, there were determined the design, and the partial substitution percentages in the total, ranging from 0 % to 35 % of RBRO and RFC incorporation in the aggregates. It was also defined the curing period, which it is related to the resistance to compression, where two and twenty-eight days of curing were determined in according to the building production standardization, consisting on the maximum evaluating strengths reached by the specimens.

Specimen productions with different RBRO and RFC percentages

Based on Costa & Appleton (2002), the specimens used to determine the concrete compressive strength are cubic or prismatic in shape, with cylinders twice the diameter being the most common. For this research, there were produced the cubic specimens in the Ceramics Sector of the Materials and Structures Department of the LEM, where the cubic specimens were manually pasted, molded and subsequently demolded, resulting in 9 representative specimens of each sample and the standard duly coded on paper with the respective dosages of each material used to carry out the mechanical tests according to the partial substitution percentages and their respective curing ages.

Therefore, for each design, there were produced 54 representative samples with an area of 25 cm2 and 0 %, 6 %, 12 %, 23 %, 29 % and 35 % total substitution percentages. In an experimental phase, it was decided to reduce the material quantities to be used in grams (figure 1), to avoid unnecessary use and the material excessive disposal, but the results were not good. There were produced nine samples and the visual aspect made it possible to identify the excess sand samples, and it was later found that it was due to the scale use in grams provided, which showed values above normal, which resulted in a new mixture weighing in kilograms.

Figure 1. Specimens produced with excess sand (a) and specimens produced with the design supplied by LEM (b).

After drying, the specimens were immersed in water for curing, which, in the opinion of Mehta & Monteiro (1994), is a process used to prevent the sudden loss of water from the concrete to the environment in the first 28 days after production, thus reducing the formation of cracks and shrinkage due to drying, making the concrete less porous and more resistant.

Solid masses preparation of the specimens

It was necessary to prepare the samples again due to the presence of coarse aggregates from the solid masses obtained during the production of the specimens. The samples were ground in laboratory equipment called a "ball mill" to adapt them to the conditions for carrying out the XRF tests using the powder method.

Solid masses chemical characterization of the specimens by XRF

There were subjected the carefully prepared samples to the XRF test using the powder method, which consisted of carrying out a quantitative elemental analysis of the chemical element concentrations present in the samples. The procedures for this test are the same as those used for the RFC chemical characterization, differing only in the waiting time for the results obtained due to the larger number of sample holders, in this case two hours.

Mechanical compressive strength test

The objective of this test was to determine the specimens´ compressive strength in the hardened state. It was tested the specimens until they broke in an Amsler machine (automatic press) and it was recorded the maximum load borne by each specimen.

The NM standard NP EN 197-1 (2005) allows the test to be carried out at two and twenty-eight days of curing age, so after immersing the specimens in water, the test was carried out and there were chosen three specimens for each curing age.

Finally, it was calculated the 3-specimen average strength for each curing age in MPa (equation 1) and then it was compared with the values established by the standard.

![]()

Where:

RC: Compressive strength [MPa];

F: Maximum force exerted on the specimen [Kgf];

A: Initial area of the specimen section [cm2].

Result and discussion

It was presented the RBRO chemical characterization taking into account the Hydrogenionic Potential. The waste was mixed with distilled water and the results were obtained over time (Table 2).

Table 2. Variation in the pH of the abrasive slurry over time

|

Time (Minutes) |

pH |

|

|

24h |

15 |

9.12 |

|

30 |

9.21 |

|

|

45 |

9.33 |

|

|

48h |

15 |

8.95 |

|

30 |

8.65 |

|

|

45 |

8.81 |

|

After analyzing the results over time, after 24 hours the pH showed average values in the range of 9.22 and then after 48 hours there was a decrease in pH, which it is possibly due to the deposit age and its respective depth, and showed average values in the 8.82 range, thus demonstrating that the RBRO is basic.

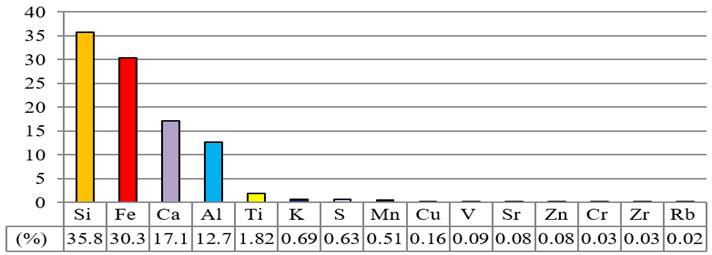

Subsequently, there were determined the main elements present in the residue, and based on the chemical composition values by using the X-ray fluorescence (XRF) and energy dispersive X-ray fluorescence (EDX) chemical analysis technique. It was possible to highlight the elements that are common in granites. Graph of figure 2 shows the variation in the chemical composition of the elements present in the waste.

Figure 2. Chemical characterization of the abrasive slurry using the XRF method.

The graph above shows the highest percentages of Silicon (Si), Iron (Fe), Calcium (Ca) and Aluminum (Al), which are in agreement with the most granite abundant constituents presented by Le Maire (1989). The major elements identified were Si and Fe, the minor elements Ca and Al and as trace elements, Ti, K, S, Mn, Cu, V, Sr, Zn, Cr, Zr, Rb, which appear in small proportions.

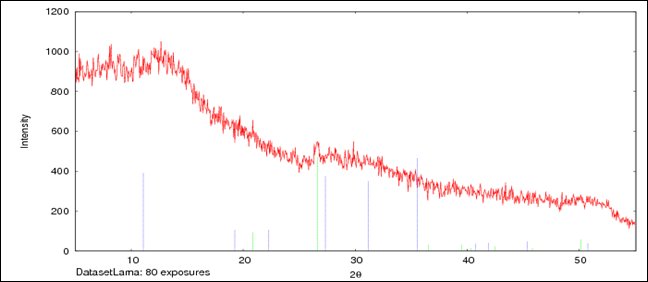

RBRO mineralogical characterization

There were obtained results of the RBRO mineralogical characterization through X-ray diffraction (XRD) analysis to identify the crystalline phases present in the waste. It was shown the results of the abrasive slurry mineralogical composition in Figure 3.

Figure 3. X-ray diffractometry spectrum of the abrasive slurry.

The spectrum resulting from the X-ray diffraction method showed intense peaks of minerals such as Quartz, and Ilite and reduced peaks of Anortite, Calcite and Magnesiorniblende.

It was found the presence of Quartz, Anortite and Magnesiorniblende in the abrasive slurry to be due to the granite constitution, with these minerals having been released during the sawing process of the blocks that indicated the blocks´ increased wear during cutting, where part of them were reduced to dust, thus becoming part of the abrasive slurry. It was identified the presence of Calcite, indicating a significant decrease in the use of lime during the processing of granite, and it is also assumed that this decrease comes from the lime used as a lubricant for the equipment (saws). It is not associated the presence of Ilite with the composition of the granite; its presence is explained by Santos et al. (2010), who state that the presence of Ilite in RBRO is related to the increase in the amount of lime during the granite processing.

RFC physical characterization

It is represented the length of the RFC particle size analysis curve by small breaks, so it is classified as an almost continuous, well-graded curve. The sand fraction dominates with around 86 %, followed by the gravel fraction with around 9 % and finally the silt-clay fraction with 4 %.

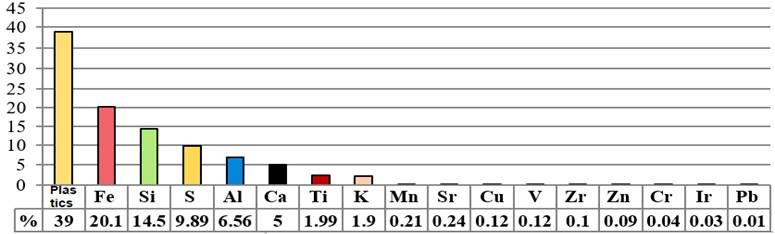

RFC Chemical characterization

It was carried out the RFC chemical characterization using the X-ray fluorescence technique. It consisted of qualitatively demonstrating the percentage values of the concentrations of the chemical elements present. Figure 4 shows the chemical composition of the RFC from the Benga Mine.

Figure 4. Chemical composition of the fine coal tailings from the Benga Mine.

In the graph above, it was identified a high percentage of plastic compounds, then a significant percentage of the major elements Fe, Si, S, Al, Ca, Ti and K which are similar to the cement raw materials´ composition, which when combined result in hydraulic binding compounds, agreeing with the quote presented by Borlotto (2017), and these elements agree with the elemental chemical characterization presented by Kossof et al., (2014), with a higher percentage of the elements Fe and Si.

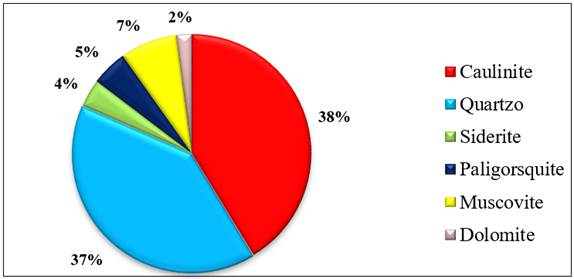

RFC Mineralogical characterization

The mineralogical characterization purpose by XRD was to identify the crystalline phases present in the RFC sample from the Benga Mine (Figure 5).

Figure 5. Percentage diagram of the RFC mineralogical composition.

According to the diagram illustrated above, Kaolinite is found in the highest percentages, followed by Quartz, in agreement with the quote by Kossof et al., (2014). And in lower percentages the minerals Siderite, Paligorsquite, Muscovite and Dolomite.

Table 3. Análise mineralógica do rejeito fino de carvão por DRX

|

Minerals |

Mineral behavior |

||

|

Solubility |

Reactivity |

||

|

Quartz (SiO2) |

37,28 |

Inert |

Inert |

|

Kaolinite [Al2Si2O5 (OH) 4] |

38,31 |

Low solubility |

Low reactivity |

|

Siderite (FeCO3) |

8,15 |

High solubility |

High reactivity |

|

Paligorsquite [(Mg,Al)2Si4O10(OH)·4(H2O)] |

7,18 |

Low solubility |

Low reactivity |

|

Muscovite [KAl2(AlSi3O10)(F,OH)2] |

7,18 |

Low solubility |

Low reactivity |

|

Dolomite [CaMg(CO3)2] |

1,93 |

Highly soluble |

Highly reactive |

Production of ecological block samples

To fulfill this objective, which concluded that the substitution maximum percentage recommended for the abrasive slurry use is 20 %, which finished that the substitution maximum percentage recommended for the RFC use is 30 % because there is a drop in the resistance to grasping after these percentages (Figure 6).

Figure 6. Specimens of ecological blocks.

Chemical characterization of the specimens’ solid masses by XRF

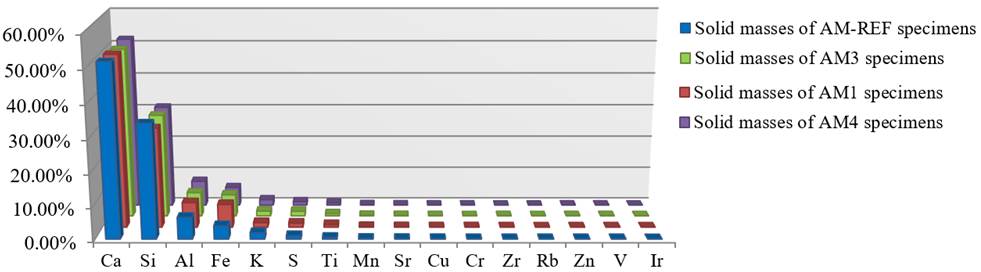

There were obtained the chemical characterization results of the solid masses using an energy dispersive X-ray fluorescence spectrometer and were interpreted using graphs. This characterization consisted of identifying the elements present in some significant solid mass samples, with the aim of comparing them with the standard mixture of blocks (Figure 7).

Figure 7. Chemical composition of the solid masses.

RBRO and RFC incorporation in different percentages results in a chemical variation elements in the solid masses, due to different factors such as: difference in contamination levels, time of disposal of each waste and the use of different chemical compounds in the processing stages. Taking into account the most significant elements, the solid masses AM3 and AM4 are similar to AM-REF in terms of Ca, Si and Al, which when combined with other chemical elements produce a hydraulic cement compound. However, they have a higher percentage of Fe than the standard sample.

The solid mass of the AM1 specimens is similar to the AM-REF sample in terms of Ca and shows a difference in values compared to AM-REF, where it has lower Si values and higher Fe and Al values.

In general, there were identified the following major elements in the four samples with RBRO and RFC different percentages: Ca, Si, Al, Fe, K and S, and there were found the following trace elements: Ti, Mn, Sr, Cu, Cr, Rb, Zn, V and Ir.

Compressive strength mechanical tests

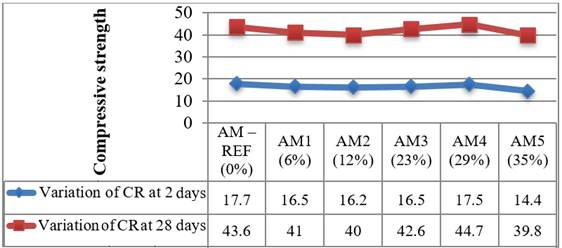

This test presents the mechanical test results for resistance to compression (see details of the calculations in Appendices V, W and X), which result from the mechanical behavior analysis of the specimens at two (2) and twenty-eight (28) curing days, taking into account the NM standard NP EN 197-1 (2005).

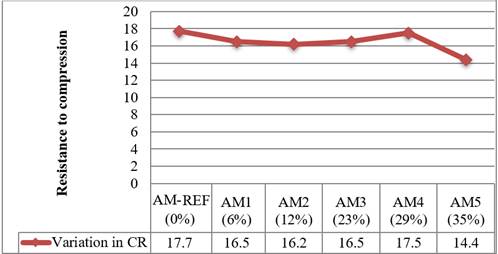

Tensile strength at 2 curing days

Figure 8 shows the results of the average compressive strength obtained at two curing days and the resulting respective percentages from RBRO and RFC incorporation. It can be seen that the specimens have not yet reached their maximum curing age, which is 28 days. All the specimens´average strengths are within the admissible standards for this curing age and the tendency is for the strength to increase over time.

Figure 8. Variation in compressive strength at 2 curing days.

The AM-REF specimens had higher CR values than all the other specimens, but the AM4 specimens had a CR close to that of AM-REF, which is probably due to the good interconnection between the aggregates and possibly until they reached the maximum curing age, the AM4 specimens had a higher resistance than the AM-REF specimens.

In the variation, it can be seen that there was a decrease in CR from 0 % to 12 % replacement, possibly due to manual compaction of the specimens, which resulted in a disparity between the values. There was then an increase in CR up to 29 % and finally a decrease at 35 % replacement.

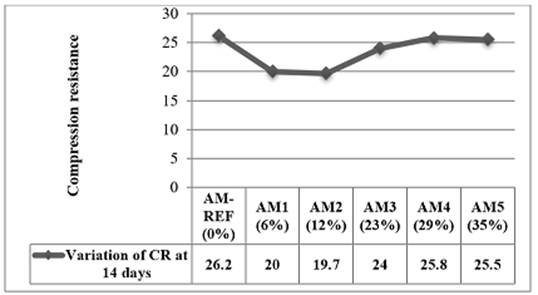

Tensile strength at 14 curing days

Figure 9 shows the compressive strength results obtained at 14 curing days and the respective percentages. It is important to note that according to the standard, it is not determined curing for this age, but the RC specimens would behave at half the maximum curing age established by the NM NP EN 197-1 standard (2005).

Figure 9. Variation in compressive strength at 14 days of curing.

At this age, the specimens showed greater resistance compared to the specimens from the two-day curing period. It can be seen that AM-REF showed a higher CR compared to all the specimens and a decrease in AM1 and AM2. There was an increase in CR in the AM3, AM4 and AM5 specimens. In the graph above, the AM-REF specimens had higher RC values than all the other specimens, but the AM4 and AM5 specimens had a RC close to that of AM-REF, which is probably due to the good interconnection between the aggregates.

In the variation, it can be seen that there was a decrease in CR from 0 % to 6 % replacement, and again a decrease at 12 %, possibly due to manual compaction of the specimens, which resulted in a disparity between the values in AM2. Then, there was an increase in CR from 29 % to 35 %.

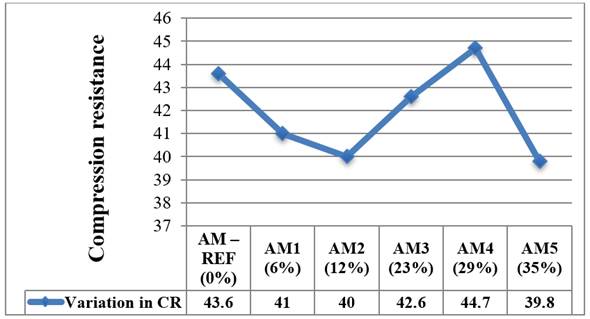

Tensile strength at 28 curing days

Figure 10 shows the compressive strength results obtained at 28 curing days and their respective percentages. For this maximum curing age established by the standard, the AM4 specimens showed the highest CR compared to AM-REF, AM1, AM2, AM3 and AM5. AM1, AM2 and AM5 showed a drop in average strengths and are not within the admissible standards for this age.

Figure 10. Variation in compressive strength at 28 curing days.

In the variation, it can be seen that there was a decrease in CR from 0 % to 12 % replacement, which is possibly due to the specimens’ manual compaction, which resulted in a disparity between these specimen values. Then there was an increase in CR from 23 % to 29 %, which showed greater resistance for this age, and finally a significant decrease in CR at 35 % replacement of the abrasive slurry and RFC.

Figure 11. Results of the variation in average compressive strength at 2 and 28 curing days.

It was found that at 2 curing days, all the specimens compared to the AM-REF specimens (without waste) presented admissible conditions for application based on the standard, and 28 days the AM1, AM2, AM5 specimens were outside the admissible standards for this age, but AM5 showed a significant decrease in CR compared to all the specimens, confirming the theory of Borlotto (2017), who states that the rate of replacement of aggregates by tailings is a very important factor, because very high proportions of tailings can increase the porosity of these blocks, increasing their water absorption rate, which decreases strength and durability.

The AM3 and AM4 specimens are within the admissible standards and the AM4 specimens showed better CR results compared to the AM-REF specimens. This is justified by Santos (2012), who states that as long as there is good homogeneity between the aggregates, the specimens will be more compact and consequently their strength will increase satisfactorily, thus showing that a good interconnection can be maintained between the abrasive slurry, the fine coal refuse and the aggregates, according to the standards in force in Mozambique.

Conclusions

The semi-quantitative analysis of the abrasive slurry was determined using the X-ray fluorescence method, and showed the presence of major elements: Si and Fe, minor elements Ca and Al and trace elements: Ti, K, S, Mn, Cu, V, Sr, Zn, Cr, Zr, Rb, which appear in small proportions. And X-ray diffraction analysis identified minerals such as calcite, quartz, anorthite, illite and magnesiorniblende.

Based on the particle size analysis test, it was found that the fine coal tailings dominate the sand fraction with a small percentage of silt and fall into the classification of fine aggregates. The chemical composition of the fine coal tailings was determined by using the X-ray fluorescence technique, where plastic compounds were identified as the major elements: Fe, Si, S, Al, Ca, Ti and K, and the trace elements: Mn, Sr, Cu, V, Zr, Zn, Cr, Ir, Pb.

It was determined the mineralogical composition of the fine coal tailings by X-ray diffraction, which identified kaolinite and quartz as the minerals with the highest percentages, followed by siderite, palygorschite, muscovite and dolomite.

In the preparation of the solid masses, it was found that water is not a constant factor during the production of blocks, and there was an increase in water from 12 % replacement, which influences the demolding of the blocks.

The compressive strength results fell as the waste substitution rate increased. Considering this, the substitution limit for the incorporation of abrasive slurry and RFC as partial aggregate is a total of 29 % according to the design presented.

It is proposed an optimum dosage of the mixture between 6 %, 23 % and 29 % RBRO and RFC as partial alternative aggregates in the production of blocks.

References

Bolotto, R. (2017). Estudo da viabilidade da técnica da utilização de rejeitos da extracção de carvão mineral na fabricação de blocos de concreto para pavimentação de vias. Programa de Pós-Graduação em Engenharia de Minas, Metalúrgica e Materiais. Universidade Federal do Rio Grande do Sul, Porto Alegre.

Costa, A & Appleton, J. (2002). Estruturas de betão I: Parte II. Departamento de Engenharia Civil.

GTK Consortium (2006). Notícia Explicativa; Volume 4; Direcção Nacional de Geologia. Ministério dos Recursos Minerais. Maputo, Moçambique.

Instituto Nacional de Normalização e de Qualidade (2005). NP EN 197-1:2005. Cimento, Parte 1: Composição, especificações e critérios de conformidade para cimentos correntes. Norma Moçambicana NM Maputo, Mozambique.

Instituto Nacional de Normalização e de Qualidade. (2014). NP EN 933-1. Ensaios das propriedades geométricas dos agregados Parte 1: Análise granulométrica. https://pdfcoffee.com/np-en-933-1-2014-pdf-free.html

José, S. & Sampaio H. (2012). Estado da arte da mineração em Moçambique: caso carvão de Moatize, Tete. Universidade Federal do Rio Grande do Sul. Brasil.

Kossof, D., Dubbin, W. E. & Alfredsson, M., Edwards, S.J. macklin, M.G. & Hudson, K.A. (2014). Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Applied Geochemistry, 51, 229-245. https://doi.org/10.1016/j.apgeochem.2014.09.010

Le Maire, R. W. (1989). A classification of igneous rocks and glossary of terms. Recommendations of the international union of geological sciences subcommíssion on the systematics of igneous rocks. Blackwell scientific publications, Oxford.

Macie, A. E. (2015). Mineração de carvão na bacia carbonífera de moatize, província de tete -noroeste de Moçambique: uma análise socioambiental. (Tese de Mestrado, Universidade de São Paulo). https://www.usp.br/teses/disponiveis/44/44144/tde-03112015

Mehta, P. K. & Monteiro, P. J. (1994). Concreto: Estruturas, Propriedades e Materiais. Pini.

Menezes, R. R., Neves, G. A. & Ferreira, H. C. (2002). O estado da arte sobre o uso de resíduos como matérias-primas cerâmicas alternativas. Revista Brasileira de Engenharia Agrícola e Ambiental, 6, 303-313. https://www.sidalc.net/search/Record/oai:scielo:S1415-43662002000200020/Description

Prochnow, T. R. & Porto, M. L. (2000). Avaliação de uma área de rejeitos da mineração de carvão com vistas a bioindicadores vegetais para metais pesados. Universidade/UFRGS.

Santos, C. R. (2012). Estudo da utilização de rejeito de carvão na fabricação de blocos de concreto para pavimentação em substituição ao agregado miúdo natural. (Tese de Mestrado, Universidade Federal do Rio Grande do Sul). http://hdl.handle.net/10183/75760

Santos, J., Silva, S., Nascimento, N., Trajano, M. & Mello, V. (2010). Caracterização da Lama Abrasiva Gerada nos Processos de Beneficiamento do Granito: Um Estudo de Caso na Granfugi Localizado em Campina Grande-Pb. XXX Encontro Nacional De Engenharia De Produção. São Carlos-SP.

Schneider, A., Friedl, M. A. & Potere, D. (2009). A new map of global urban extent from MODIS satellite dat. Environmental Research Letters, 4(4). https://doi.org/10.1088/1748-9326/4/4/044003

Silva, S. A. (1998). Caracterização do resíduo de serragem de blocos de granito. Estudo do potencial de aplicação na fabricação de argamassas de assentamento e de tijolos de solo-cimento. Dissertação. (Tese de Mestrado, Universidade Federal do Espírito Santo, Vitória).